With the HelioBrush® presents Daetwyler Graphics a new treatment of the surface of copper cylinders. A unique tool to achieve predictable, stable and controllable results independent from circumference and size of cylinder. The result gives a well-compact homogeneous surface due to closer Rz and Rmax values. Cylinders machined using HelioBrush® show significantly less scumming (hazing) at high roughnesses.

HelioBrush®

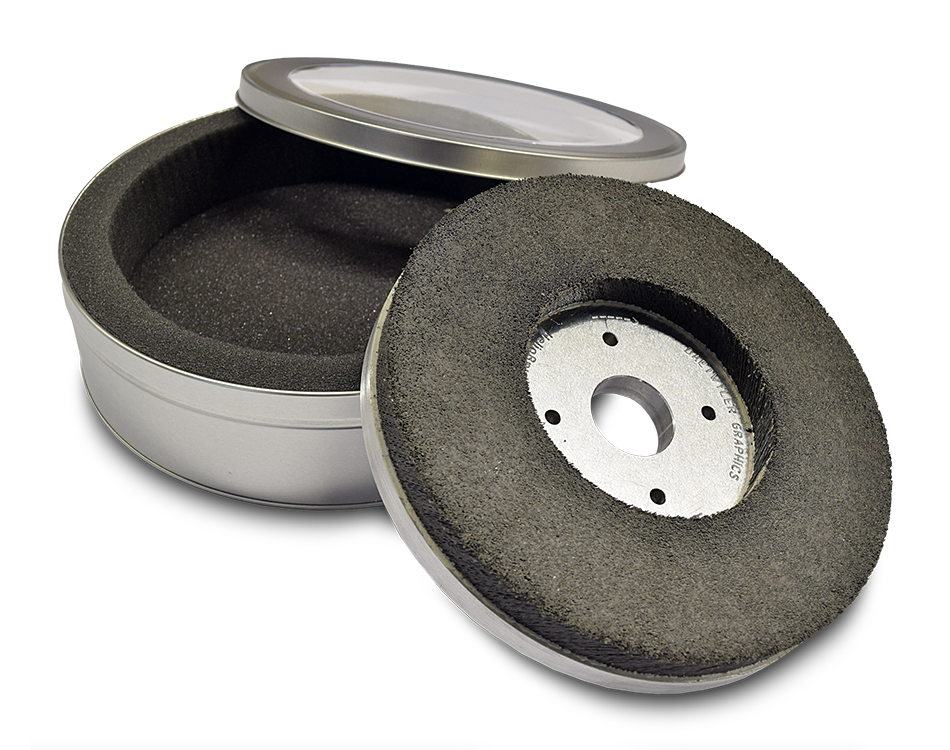

The new polishing media

FEATURES

- Better print results due to less likelihood for hazing with higher roughness values

- Long life time

- Less stone usage = less sludge = less filter usage

- The usage of the paperband head for crosshatch pattern no more needed

- No loss of Rz value once chrome coated (Rz in Cu = Rz in Cr)

- Roughness can easier be changed by numbers of strokes

| No. of stroke | 6 | 12 | 18 | 24 | 30 |

|---|---|---|---|---|---|

| Roughness Rz [µm] |

0.6 | 0.5 | 0.4 | 0.3 | 0.25 |

Further information

A detailed brochure is also available to download as a PDF document:

HelioBrush®

For further question you can contact us at service@daetwyler-graphics.ch

TECHNICAL SPECIFICATIONS AND ORDER NUMBERS

TECHNICAL SPECIFICATIONS

FOR WHICH MACHINE TYPE IS THE NEW HELIOBRUSH® AVAILABLE?

A retrofit is available for any FINISHSTAR P-1610 CU and FINISHSTAR P-1610 CU/CR built after 2008

SCOPE OF UPGRADE?

Planetary gear

Splash guard

Optimized grinding program adapted to your needs

Training by technician

HOW TO GET THE UPGRADE ON YOUR MACHINE?

Contact us for more details. We will gladly work out a quotation with you, based on your needs.

ACCESSORIES - ORDER NUMBERS

600844 | HelioBrush®