One of the most critical process steps in rotogravure cylinder making is the definition of the cylinder geometry. Nowadays, the most common process to determine the geometry is cutting on a CFM. Only our OEM-tools, called HelioFace T-CUT, ensure a stable, reproducible and efficient turning process in your cylinder production. This tool can either be used for copper or chrome.

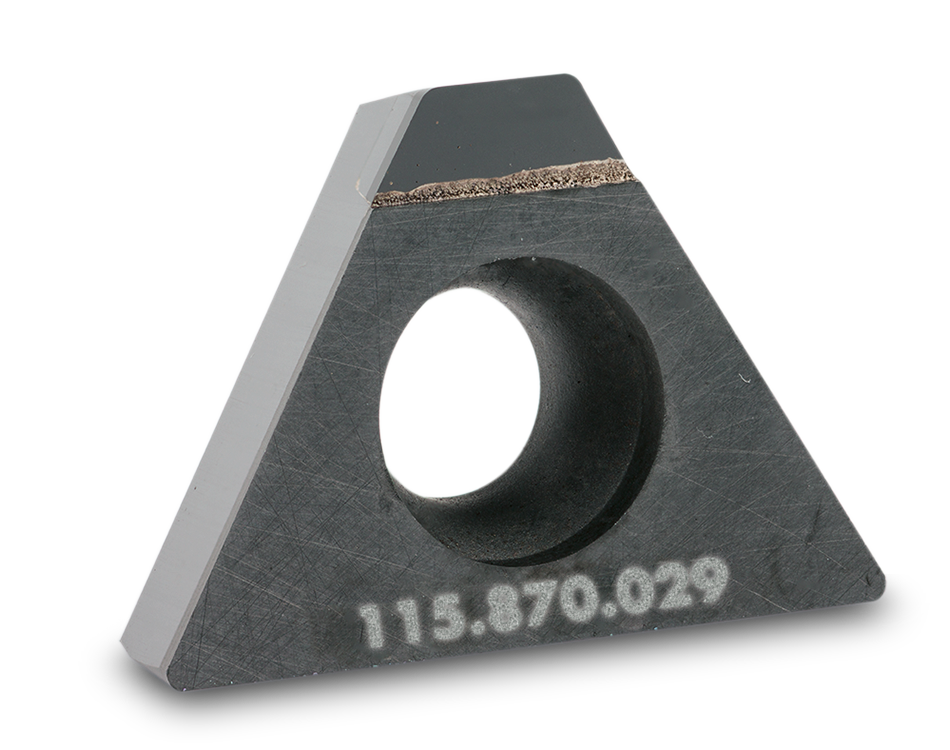

HelioFace T-CUT

Standard face cutting plate for CFM

FEATURES

- Long tool life

- Low tool costs

- Quick changeover – Reduced calibration time

- Highly precise cylinder surfaces

- Special cutting angle for higher process reliability

- Very high parallelism – Optimal ink transfer

- Finest surface structure – Reduced stone consumption

FURTHER INFORMATION

A detailed brochure is available to download as a PDF document:

HelioFace T-CUT

For further question you can contact us at parts@daetwyler-graphics.ch

TECHNICAL SPECIFICATIONS AND ORDER NUMBERS

OUR RECOMMENDATION

Along with the face cutting tool, we can additionally supply side processing tools. The Side Processing Plate is used to process cylinder sides, angles and the tapers on the cylinder face.

ACCESSORIES - ORDER NUMBERS

Face cutting

115.870.029 | HelioFace T-CUT

115.870.003 | Carbide Spacer

Side processing

207622 | Side Processing Plate

200577 | Carbide Spacer

Accessories

128403 | Spacer Screw for Carbide Spacer

207623 | Torx Screw M3,5 for Cutting Plate